Fuel Rods

This is a breakdown of how Fuel Rods work, for information on nuclear fuel itself, you want Nuclear FuelNuclear FuelNuclear fuel is fuel used inside of the nuclear industry broadly. Specifically for Nuclear Reactors, nuclear fuel is necessary for a fissile reaction. As is the name, nuclear fuel is radioactive - it decays over time and releases excess neutrons. This makes it highly energy dense and optimal for the nuclear sector. Whenever you hear someone talking about nuclear fuel, the first thing you can think about is Uranium. Being radioactive in it of itself, after enrichment, enriched uranium is a commo.

Fuel rods are made out of the fissile material that is wanted for the reactor, then experience different things. Uranium Dioxide fuel is pelleted and filled into metallic tubes, which have reactor claddingreactor claddingCladding is the thin walled metal tube that composes the outside of a fuel rod. It's purpose is to prevent corrosion of the fuel by the coolant & release of fission contents into the coolant. Although Zirconium alloy is common, aluminum and stainless steel is also used. Cladding Types Zirconium alloy has been used for so long due to it's properties being very good for nuclear reactors. * New research suggests that there is an alternative - SiGA cladding. This cladding is made from silicon car of ZirconiumZirconiumZirconium is a metal used in Nuclear Reactor cladding Zirconium has excellent heat transfer properties and allows for efficient heat transfer. However, it has a negative reaction called Zircaloy hydriding, where zirconium and hydrogen combine for form zirconium hydride, embrittling reactor cladding and resulting in perforations. or stainless steel, and then these tubes are sealed.

In a PWR reactorPWR reactorThis reactor is a PWR reactor - a pressurized water reactor. This is a specific type of Nuclear Reactor--in that it is pressurized water. This is also the most common type of reactor used and produced. The fuel rods are pressurized with helium, and the fission gas products result in more stability; as fuel "burns" in the reactor, the density increases resulting in small voids developing. Helium pressurization is necessary as these voids can cause potential rupture of fuel rods. Furthermore, the, fuel is cylindrical rods into bundles, where fuel is bundled and the cladding gap filled with helium to help with heat transfer. Approximately 179-264 fuel rods are contained per bundle then 121-193 bundles are contained within the reactor core, bundled 14x14 or 17x17. Control rods are inserted directly from the top to the fuel bundle, and the oxide is dried.

BWR Reactor

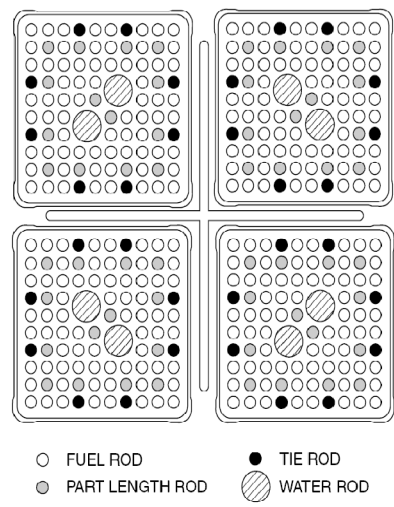

In a BWR reactorBWR reactorA boiling water reactor uses Light Water as both coolant and neutron moderator. The second most used reactor, next to the PWR reactors, there are approximately 75 plants in current operation. The efficiency of these reactors is about 46%, with 33-34% in practice. Enriched uranium is used as nuclear fuel, as light water absorbs too many neutrons to use Uranium that is natural. Light water is not as good of a moderator compared to Heavy Water or graphite, but it is good as in the event of a LOCA o, the fuel is similar except there is a thin tube surrounding each bundle, there are a varying amount of fuel rods per bundle, and each rod is filled with helium to about 300 kPa.

in a GE-14 fuel bundle, there are 70 fuel rods, 8 fuel tie rods, 14 partial length, and 2 water rods.

Partial length rods

Tie rods have threaded end plugs for the engagement of the tie plates. the others have slip fittings for those tie plates. The design of the tie plates allows for springs to let the expansion and contraction of metal under heated conditions to occur.

Water rods

Water rods are made of zircaloy-2, and are hollow. Holes in these fuel rods allow coolant flow. The water rods contain fuel spacers via welded tabs spaced 21 inches.

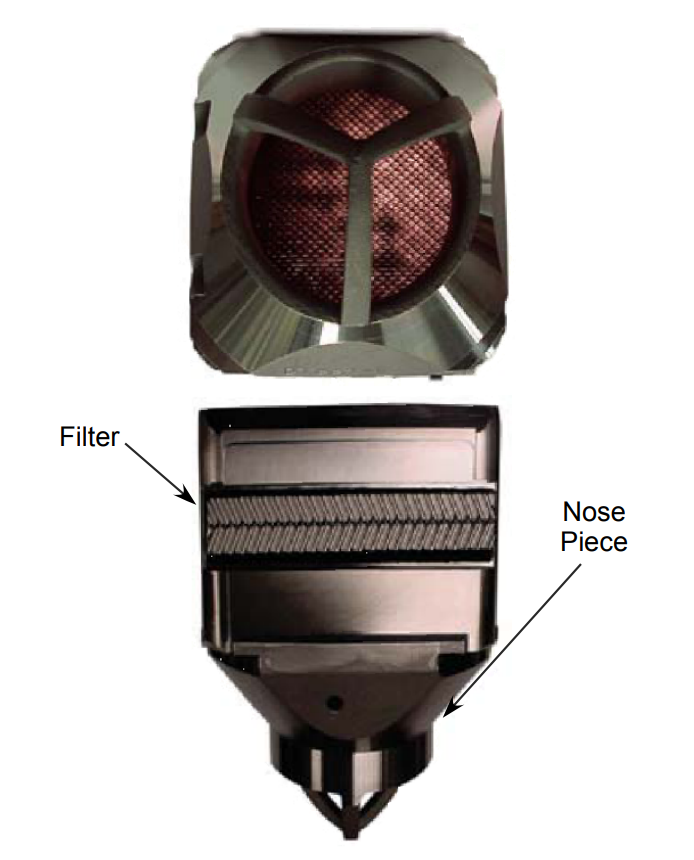

Tie plates are also used. Tie plates are used for the alignment and support of the fuel rods on the fuel bundle. An integral part of the upper tie plate, for example, is the lifting handle. The lower tie plate positions the fuel rods more, and there are holes for 10% of flow to bypass the fuel (core flow), with 90% of flow directed inside of the channel. This tie plate also has a filter for the prevention of foreign material to enter the fuel rod region.

When fuel is loaded, the orientation is very important, and can be verified by the channel fasteners, orientation boss, channel spacers, ID numbers of handles, and square pattern; however poor water quality may result in unverifiable fuel loading operations.